A general assumption regarding socket sizes is that you have to arrange or measure them in an ascending or descending order. It is not true because the measurements and sizes of sockets are not ours simple as you think. It is a bit technical, as there are different measurement standards, including SAE and metric systems.

While using these tools, selecting the correct size for accurate compilation and the best results is essential. You can only select the appropriate socket size if you know all the sizes. The sizes of sockets depend on the dimensions of the drive size. Hence from smallest to largest, they are arranged in ascending order. In this article, we will tell you everything about standard socket sizes in order and the types of sockets available in the market.

The Commonly Available Drive Size

Drive is present on the square part of the Ratchet in a socket wrench. It is available in a variety of sizes such as

- ⅜” drives

- ½” drives

- 1” drives

- ¼” drives.

Socket Sizes In Order Chart

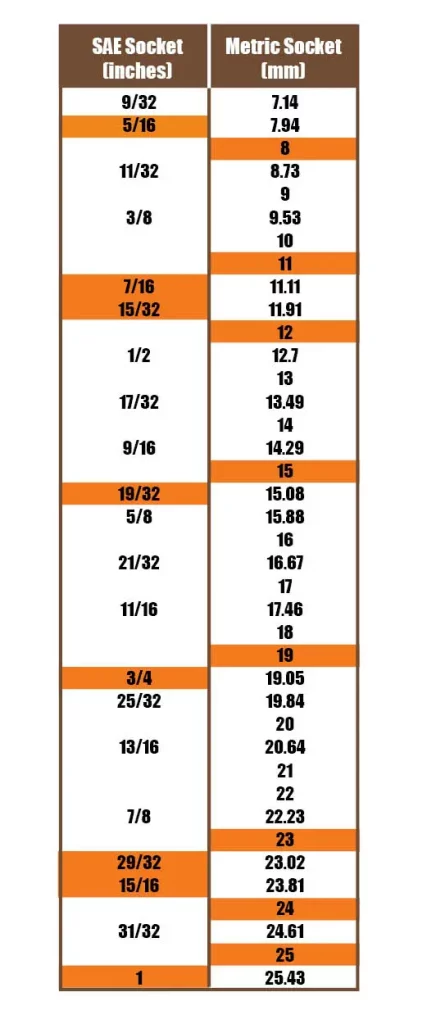

The socket size is available in two international standards: the metric socket size and the SAE socket size. Below are the size chart of both standard measurements.

Metric Socket Size Chart & SAE Socket Size chart:

Types of Sockets

Based on the drive size, socket sizes are divided into different sizes. There is a huge collection of Sockets available in SAE and metric standard which you can use with the help of different types of wrenches. Following are some of the common types of sockets

Also Read: Difference Between Mobile Home Water Heater and Regular Water Heater

- Point Sockets

12-point sockets are among the best type of pocket sockets. It is easy and convenient to use because it can fit in the hardware in any of the 12 positions. When the tool is easy to align it becomes much easier to use. It is a good choice for both household and light tasks.

On the other hand, if you talk about 6 point socket then it is more useful for tough tasks requiring a high amount of torque. 6 points socket is fixed more powerfully and there is no slip which makes it a more durable option.

- Impact Sockets

People commonly have different types of sockets and handles but they cannot use them without other parts. An impact socket is a tough type of socket that only works with the calibration of other tools. For example pneumatic impact wrench. To create a higher torque you need to build a set of sockets. The sockets are mostly more strong and more robust than the other type of sockets.

- Deep And Shallow Sockets

If you do a comparison between shallow or deep sockets then a shallow socket will not touch the valves on the top of the socket dimensions. So, it is not a good choice if you have a confined space to perform your work.

Conclusion

We hope that the above-mentioned socket sizes in order chart and the types of sockets will help you in differentiating what kind of socket size you should use for your work. For accurate work, it is important to have the correct socket size. The drive size as well as socket size builds the exact torque for the work. If you have any queries, let us know in the comments section we will be glad to resolve your problem.